產品說明

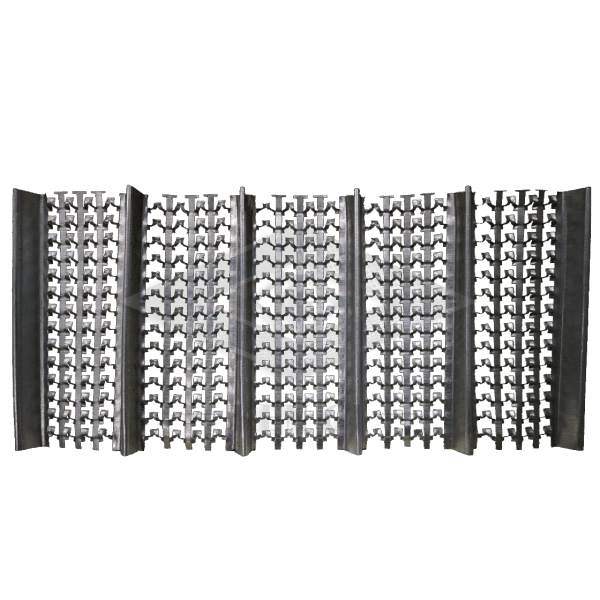

金屬免拆模板(易披網)係採用進口或國產之熱浸鍍鋅鋼板製造並符合CNS、JIS、ASTM、BS等標準規範。本公司建材機器(易披網機、有筋網機)暨整廠設備外銷世界各國,因此製網技術與品質保證第一。

優異特性

- 免拆除

金屬免拆模板(易披網)係供結構使用之永久性模板,混凝土澆置完成,不需拆除、清理、打油,可大量節省勞工費用及時間,有助於趕工進度。

- 提供優異接合面

金屬免拆模板(易披網)在混凝土澆置後,會於結構表面自然形成一組粗粒表面,不需再作鑿除、打毛等表面處理即可施行第二次灌漿或粉刷工作,並能提供有效及優異的結構接合面。

- 減低壓力

金屬免拆模板(易披網)的網狀區開口可協助分散澆置時水泥砂漿所產生的水壓,可節省木模或鋼模所需的支撐木材。因此可降低人工及材料費用。

- 體積小,重量輕

金屬免拆模板(易披網)本身重量比木模輕很多加上體積又小,搬運非常容易,特別在高樓施工現場更能感受其輕巧性,使施工進度加速並節省費用。

- 優越的現場工作性

金屬免拆模板(易披網)所使用的材料很容易切割、彎曲成所需要的設計形狀或不規則表面,例如在肘節螺栓本產品並可先行摺曲通過結構配筋再展開使用,此種優越的現場工作性,木模、鋼模絕對無法達成。也因此種特性在裝設模板時可節省大量的時間及人工成本,在設計時更能保有計劃的彈性,使設計更臻於完善。

- 節省模板支撐材

金屬免拆模板(易披網)在許多情形下,模板支撐材可省去不用而將本產品直接固定在RC鋼筋上,不但節省支撐材及人工費用更能增加工作進度。

- 防止暴模

金屬免拆模板(易披網)模板交處及模板與鋼筋的牢靠接合,可有效的防止模板與混凝土澆置作業中暴裂而影響施工之進度,可提高施工效率、減少材料損耗。

- 工地清潔美觀

金屬免拆模板(易披網)體積小又輕,易於置放且無鋼釘、汙油等雜物,使工地保持清潔美觀。

- 可防止混凝土表面產生裂縫

金屬免拆模板(易披網)為一鋼網具有高強度之張力可防止混凝土表面產生裂縫。

產品特性

- 灌漿後免拆模板

- 免清理、省搬運、庫存少空間

- 鐵絲易綁、鋼筋易穿透固定

- 重量輕易搬運

- 灌漿後平整快

- 增加結構強度(可減少鋼筋用量)

- 牆面防撞、防震、防火

用途

- 大型建築及土木工程、大地工程,如施工縫、獨立基礎地樑、筏式基礎、擋土牆

- 下水道工程、地下鐵、捷運系統、核能電廠、船塢、地基橋面

- 不規則或曲面造型、高樓、海洋工程等重大工程,均可作為鋼筋混泥土永久性模板之最佳補牆材料。

- RC結構或H鋼構之外牆

- 擋土牆(圓弧形狀牆面均可)

- 圍牆、隧道、橋樑

- 水壩、儲槽